-

Posts

6,136 -

Joined

-

Last visited

-

Days Won

177

Content Type

Profiles

Articles

TU Classifieds

Glossary

Website Links

Forums

Gallery

Store

Everything posted by RayburnGuy

-

I've tried all of the methods described above at one time or another. For me personally I like to use a Popsicle stick and do it like what gone2long described above. I seem to have more control over where the splatter goes doing it this way. If you want bigger splatter you can use thicker paint where thinner paint will usually create smaller splatter. Air pressure also plays a role in the end result, but that's true of most splatter techniques. Ben

-

My pleasure ING. Hope everything works out for you. Ben

-

Best advice I can give you is to try it and see how it works. If you have trouble getting the lead to flow all the way to the bottom then you can try pouring the lead at a hotter temp and heating up the angle iron with a torch before pouring. Unless your pouring really long bodies I don't believe you'll have much trouble. good luck, Ben

-

Help Removing Epoxy Clear Coat From Hook Holders?

RayburnGuy replied to reallison's topic in Hard Baits

I'm with Bob about covering the hangers when applying top coat. By doing so you are assured the entire surface of the lure is covered and that there is no chance of water getting to the body of your bait. And like he said, it only takes a minute or so to remove the top coat from the hook hangers. Ben -

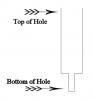

The hole you pour through will be the same size as the body of the lure your making. The small hole at the bottom of the larger hole will be to hold your wire. If your wire is stiff, straight and the bottom hole is sized correctly to match the size wire your using it should hold the wire without any further help. Below is a drawing of what the hole should look like. The larger portion of the hole will be at the top of the angle iron. This is where the lead will be poured. The smaller hole at the bottom is where the wire will fit. By clamping the two angle irons back to back, and drilling where the two meet, you should end up with one half of the cavity in each piece of angle iron. Ben

-

Looking For J Plug Or Any Salmon Plug Bait Blanks

RayburnGuy replied to WalleyeAndy's topic in Hard Baits

Is this what your looking for? Ben http://www.luhrjensen.com/luhr-jensen/lures/hard-baits/j-plugandtrade/J-Plug.html- 9 replies

-

- 1

-

-

- salmon plugs

- blanks

-

(and 1 more)

Tagged with:

-

The 2 pieces of angle iron ARE the mold ING. They need to be clamped together and then the hole is drilled where they meet. That way when the clamps are removed and the 2 pieces separated there will be one half of the drilled hole on each piece of angle iron. Below is a crude drawing of what I'm talking about. Ben

-

You can make your own mold to pour these weights fairly easy. All you will need is 2 short pieces of angle iron and a drill press. You will need to clamp the 2 pieces of angle iron together back to back. Then drill a hole the size of the wire that will run through the center of the weight. This wire will need to be a wee bit larger than the wire you will be using to build the lure for obvious reasons. Without moving the angle iron now drill a hole in the same place as the previous hole you just drilled. You will need to drill this hole shallower than the first hole so you have a place to hold the wire centered. By drilling a shallower second hole you will have a place to fit a straight piece of wire in the mold that will run up through the larger hole. The wire you use will need to be straight and smooth to make removing it from the lead easier after the weight is poured. The wire should be removed while the lead is still fairly hot. This will also make removing it easier. This will give you a weight like the old Mojo weights. Ben

-

I would give that a try Les, but I'm not set up to pour plastics and I can't really justify the expense of getting set up just to pour plastics for myself no matter how much I'd love to give it a try. Ben

-

They did work well on both the Carolina rig and as a top water bait. They also worked well when fished on a Texas rig with the sinker pegged a few inches up the line or with a split shot crimped on the line. I used to fish tubes year round. Not sure why I quit fishing them as much as I once did. It's funny how we're always looking for the "latest and greatest" and seem to forget the "tried and true". Ben

-

Hey guys, Do any of you know if anyone is still making floating tubes? I know Gene Larew made them at one time and seems like there were a couple of others that made them as well, but haven't seen any in years. thanks, Ben p.s. I've used the "packing peanut" trick to make tubes float, but the tentacles on the old floating tubes floated as well since the whole thing was filled with microspheres. They also floated up slower than tubes with the packing peanuts in them.

-

Solarfall makes some of the best looking baits I have locked an eyeball on and the only power tool I've ever seen him use in his videos is a jig saw for cutting out the basic profile of the bait. Everything else is done with hand tools. It's worth the time to take a look at some of his videos. Ben

-

LPO = Lure Parts Online They own TU.

-

Just because it died doesn't mean the fun is over. Paint a target on it and go to town. Ben

-

I bought some 80 lb. #2's from LPO a while back. Haven't pull tested them, but the wire isn't much thicker than the 20 lb. Ben

-

That should make the brush softer so I can see how that would help keep bubbles out of the finish. Only drawback is that it might not allow you to load as much epoxy onto your brush. May have to give this one a try though. Thanks Chuck. Ben

-

One of my pet peeves when welding was when people would ask me if a repair I'd made on a piece of their equipment was going to hold. I'd look them straight in the eye and tell them "it broke when it was new didn't it". That usually shut them up. Ben

-

Nice work Travis. Great job on the mold. Ben

-

Kudos to you Woodie. Not many folks would share specific information about where to catch fish. Nice job man. Ben

-

Aren't we all? Ben

-

Epoxy would be my choice if I were only going to do a few baits. You don't mention what species of fish your going after. If your fishing for bass then one coat of epoxy is plenty. If your fishing for toothy critters then I'd follow Gino's advice and apply two coats. good luck, Ben

-

If your spraying clear coat just remember to thoroughly clean your airbrush as soon as your done spraying. I disassemble mine completely and clean it in acetone after spraying DN through it and so far have not experienced a single problem. Ben

-

Good to know Sonoman. thanks, Ben

-

Sorry about that. Guess I was having a Homer Simpson moment. http://www.tackleunderground.com/community/topic/14042-swimbait-prototype-and-body-thickness-question/?hl=%2Bswimbait+%2Bratio Ben

-

If your a hobby builder Dale I doubt you'll ever wear out an airbrush. Like Woodie said he has never retired an airbrush, but does rebuild them. And he paints a LOT of baits. Unless there's an operator error on your part (bent needle/nozzle, etc.) your highly unlikely to wear something out. Another way parts have to be replaced is doing something stupid like dropping a $30 nozzle for an Iwata Hi-Line in the trashcan. Don't ask me how I know. Ben