-

Posts

463 -

Joined

-

Last visited

-

Days Won

12

Content Type

Profiles

Articles

TU Classifieds

Glossary

Website Links

Forums

Gallery

Store

Everything posted by SlowFISH

-

Will not laminate with a laminate plate/2nd pour or if you shoot it with 2 injectors at same time (ex Shooting Star system) will it laminate? J.

-

FYI - I picked up the Slider hooks 2/0 and 3/0 sizes..... they are alot more beefy in wire size (.050" and .055") than I'd thought they would be considering they are "slider" hooks... figured I'd let you guys know in case anyone was interested in the hooks - I like the strength as my goal is to use them in the weeds anyway. Also.... the 3/0 Black Nickel hooks must be tempered as bending back and forth on the bend near the hook eye will break it... but the 2/0 hooks (bronze) I was able to twist the eye up to 90 degrees - back past the original position - and then back into original position.... so if you want something you can adjust a little to make your jig just as you like - these may be the ticket. J.

-

+2 on Needle Nose vice grips.... work real nice to twist the wire tight. J.

-

Those hooks look perfect for what I need!!!!! Thanks so much.... I knew there were hooks out there - the Capt Hook (Gammy G584LS) looks very similar to the Owner hook minus a little bending... the Slider ones look just like the VMC hooks... I should be good between those options!!! J.

-

That might be an option... I'll take a look as I have some eyelets... Might also try to contact VMC/Owner adn see if those hook will be available as that would be my first choice to insure the strength of the ji. J.

-

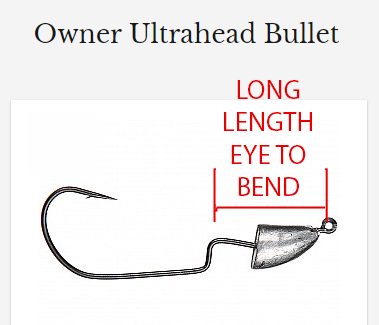

Hey guys looking for some guidance / help.... I want to make a custom jig mold based on the the VMC rugby jig - but with a more pointed lead/head for fishing the weeds. I'm having a hard time finding a hook that would be suitable. It needs to be a worm hook with a "z" bend... but have extra length in the upper portion between the eye and the bend. Owner has the Ultra Head jigs with a hook that would work great - but I don't see that hook offered in their catalog. Obviously VMC has the Rugby jig... but don't offer just the hook as far as I can tell.... and I've already purchased their 7319/6319 extra length worm hooks.... they "almost" work - but are just a bit short to add enough weight for what I want to do. This is pic of the owner ultrahead with a REALLY long segment between the eye and bend to explain what I'm looking for. If anyone has a lead on where I might find something that would work - would be greatly appreciated... I'm not particular to any brand... so fire away with any suggestions..... other than just living with the rugby jigs!!! LOL!! Thanks. J.

-

Well you got the chrome look!!!!! Would love to read your tutorial and understand what materials you're using and the pro's / con's of your method. Nice work!! J.

- 7 replies

-

- 1

-

-

- chrome

- heat tranfer

-

(and 1 more)

Tagged with:

-

This place in in NYC.... but atleast you can read up on the products... I've used the ultracal.... it's great stuff.... you just have to mix it with a sifter slowly - isn't really a pain - but obviously no as easy as standard POP. J. http://shop.sculpt.com/usg-ultracal-30-25lb-box.html http://shop.sculpt.com/usg-hydrocal-white-25lb-box.html

- 19 replies

-

I think what's really cool is you're doing most of your work with very basic tools... no CNC or high end carving tools.... a band saw, dremel and a box cutter.... awaesome! J.

-

I think Smooth-On makes some aluminum filled resins... I've been interested in them but the cost sq/in vs. other materials isn't even close to being reasonable unless you only want to make 1 mold and/or back fill most of the mold with something more cost effective. I machine molds from Urethane Resin - Freeman 5169/5179 Foundry Tooling Board - used for making thermofom molds/stuff like that. It works reasonably well... but can/will distort from heat as it gets hot.... so you really need to clamp it well. Advantage is as Bob alluded to... you can machine it very easily - even a novice like myself can cut thin ribbed/detailed parts with really small mills and get nice results without breaking tools.... no flood or coolant to mess with and you can take some deep cuts with a small machine (TAIG) compared to aluminum. I wouldn't recommend for production as with any resin mold - much longer to cool down and the clamping issue... but it's somewhat reasonable cost wise compared to aluminum. Perfect for a hobbyist/novice machinist. (And I use machinist lightly!! LOL!) Real interested to see hear how the epoxy/aluminum combo works... if it can pull heat from the pour quick - that would be nice - as it's the one negative of the resin based (2 part) molds I hate. J.

- 19 replies

-

A chrome look is possible to achieve with some of these products - but the one factor not in your favor is it continuing to look like chrome after it's painted... I gave up and just use a silver metallic (or foil like mentioned above). Most "chrome" paints and finishes do not want to be overcoated... so the second you put epoxy or anything over them - the dull out and look like a silver pretty quick. And FYI on the Spazstix stuff.... it's beautiful sprayed on the inside of clear plastic parts backed/protected with black... but you can't reverse it.... ie laying down black then spraying the silver as it's VERY fragile - if you touch it you'll out a finger print on it which you CAN'T remove - so you try and overcoat it - which dulls it and you might as well just have bought some rustolem! Other options I've looked at but haven't tried are foil transfers... like gold leaf/etc.... might work depending on you lure shape. J.

-

From what I remember 24 before each one... Id spray each morning before I left for work... possible I sprayed one layer at night after work... which would have been about 12-15 hours later. J.

-

Great.... now I'll assume it's something I did!!! LOL!! I sprayed multiple coats..... the last coat went on 24 hours before I used the mold.... it's possible it didn't cure fully as it's been a little cooler and damp here... but it melted off everything - all layers back down to the mold itself. I did some searches and seems like Rustoleum Engine paint is one of the options that works.... I'll pick up a can this weekend and see how it goes. J.

-

It's not the mold resin.... it coated the molds just fine, was smooth and had decent hardness to it - plus this stuff is engineer to be painted... it's used in the prototyping industry for models/forms/etc.... but once the plastisol was shot in the cavity all hell broken loose... and on the faces of the mold that were not in contact with the plastisol - there is no damage issue... just where the hot plastic went in... that's why I'm asking what brand/type.... cause the stuff I used (Duplicolor High Temp Cermaic) doesn't play well with baits!! LOL!! J.

-

Hey guys.... I have a resin mold I tried to coat in Hi-Temp paint (Duplicolor High Heat Ceramic) to give a nice smooth finish.... first shot and this stuff reacted with the plastisol and melted... basically locking the mold shut - after i pry'd it open - half of it was on/in the bait- the rest bubbling, tacky and could be wiped off the mold. So - for anyone who has used high-temp paint in a mold and had good result - what brand/color did you buy... figured I ask before I go through the trial and error to find one that works... And not looking for alternatives like Epoxy/Elmers etc.... looking for a aerosol spray paint so I can coat all the small area I have with light coats and not gum it up brushing some thing in the mold. Thanks! J.

-

As many have stated... Sealers that have worked for me on POP... Epoxy (thinned) / Elmers / Dick Nites Lurecoat (had to use it before it hardended in can!!) Things that didn't work well... Rustoleum Clear Coat (acrylic) - baits just stick to that stuff and not just POP molds / Epoxy (not thinned) - it sealed but ruined the finish as it cloged all small details. Honestly - Epoxy and Elmers are super easy to find anywhere, cheap and once you find a method to apply you like - work just fine. J.

-

+1 on probe style.... you'll find the top surface of the plastic (where a IR thermo will measure) is much COOLER than the center if you are using a microwave to heat the plastic.... and it's a drastic difference in temperature. I have the probe style - and use it to stir... you'll be amazed at the difference in temps you'll see when you place it (Top/Bot/Middle) of a heated cup of plastic. I'd imagine if you're using a presto with a stirrer an IR could work as the plastic is constantly churned up. J.

-

Agree with all above - but if you are open to learning, spending ALOT of time and cash - it can be very rewarding... I have a small Taig CNC... it's not something I'd used for production of molds - but for personal stuff it's a good little affordable machine. There are ALOT of those machine out there too - so a pretty deep knowledge base to investigate to see it is for you.... I've given up on machining aluminum - as I agree - flood coolant is probably required - notably if your using very small endmils under 1/8" dia - which are tough on a small inaccurate machines to begin with.... I machine alot of the resins for my molds - and it's great for that as I don't need coolant and it's way more forgiving of a "non-machinist" way of doing things !!!!! J.

-

If you don't wanna waste money/time/etc... get a different hobby!!! LOL!!! Innovation cost money.... no matter if your the most frugal of people - just be prepared to have things go wrong and always buy a little more material/supplies than you THINK you'll need.... you'll need it!! LOL!! Good luck! J.

-

Anglinarcher is right on with his points.... You can try a PLA release film.... it's basically a water based spray on film that will allow you to separate one part from the other when making fiberglass parts. I used it while making a few motorcycle fenders/molds. You spray it on - let it dry - layup the other part - then after it cures - use water to dissolve the PLA while trying your best to pull the molds apart. Even with the PLA stuff - you gotta work it.... most of this stuff is expected to be used on big highly drafted parts - and even those you gotta bang around a bit.... on small things like we use - its tough. Look up the PLA release film online.... it's not expensive from what I recall... J.

-

I believe the skirts are placed in the mold - across the body - the mold is then shot with plastic - somewhat locking the skirts in place. J.

-

Sometimes warming the mold helps.... do not make it super hot... but a solid warm.... if your shooting a cold mold - it can cause some issues in those fine detail areas. And try keeping the injector warm as well.... that has been a huge difference maker for me.... in a cold basement, using a micro and sometimes long periods between shots - my injector would cool off too much between the shots... which cools the plastic fast when you suck it up then gives you incomplete baits.... If you sprue is cooling off around the injector - that's probably part of the issue. Sometimes if I just shooting a very small amount to test a new mold - I'll suck up plastic in the injector... shoot it right back into the cup - which heats the injector - then nuke the plastic a few more seconds to bring that temp back up - then suck it up and shoot... those aluminum injectors can cool quick and cause issues.... incomplete shots, etc. J.

-

Just buy some small diameter aluminum tubing (from a hobby store or online). Get a diameter that just slides over your guards snug - or trim the guards down (thin them out) enough to fit the tube. The length of the tubes should be just longer than the guards. I slide them on prior to power coating (fluid bed) - slide on tube over guard - heat with gun, coat paint in fluid bed, then place in over to cure with the tubes in place. You'll them need to give them a little twist/bend to break the end free from the powder paint (rarely effects finish - only issue I've had is on jigs I goobered the paint on too thick). You can reuse them.... don't worry about different colors - I've used the same ones over and over with different paint and no issue. Plus they are cheap - just cut more as needed. I do recommend flaring the end of the tube slightly with a tool/nail so you can slide them on snug esaily... if you leave room in the tube - they fibers will distort/bend some. J.

- 18 replies

-

- 1

-

-

- weedguard

- powder coat

-

(and 2 more)

Tagged with:

-

I'd also recommend cutting the pieces up as small as possible.... the melt quicker which in turn means you shouldn't have to heat as long or as much when melting them down. Also you might wanna make sure when you "suck up" the plastic the nossle/tip of the injector is fully submersed... if it comes out of the plastic - you'll pull air up in it that will end up in your bait when you shoot it. J.

-

I agree about the 2X being difficult - as it's real hard to measure accurately - not such a big deal if you want something BLACK and don't care too much about how much goes in.... but really hard to control if you just want a "couple drops"..... J.