Cmiller23

TU Member-

Posts

79 -

Joined

-

Last visited

Content Type

Profiles

Articles

TU Classifieds

Glossary

Website Links

Forums

Gallery

Store

Everything posted by Cmiller23

-

-

-

-

-

Has anyone messed with baking paint on the unpainted crankbait bodies that you can buy? What type of paint do you use?

-

-

apparently it didnt react good to paint?

-

Sorry for the slow response i actually just got done with finals... I'm glad to see that this post actually generated some interest. Vodkaman - I have read your post regarding the strouhal number and enjoyed doing so. Vortex shedding is going to be a big part of this study as I will actually be doing tests in a wind tunnel rather than water. First I had to make sure and match the Reynolds numbers between air and water.... It seems that if you have a reel that pulls in 28" of line per turn at 1 turn/second your reeling at approximately 0.7 m/s... But in air with matching reynolds number the lure would have to be moving (or air moving around the lure in this case) at approx 9-10 m/s. I will most likely be using the strouhal number in this study at some point for the very reason of calculating the frequency. Clint M - I actually do not use hardly any technical aspects when making my lures. I use the tried and true "eyeball method", now this does cause some inefficiencies in the process and I recognize that. But Im only building for fun and for my personal use. Also because I am a poor college student and cannot afford accurate machines. All I use is a coping saw, belt sander, dremel and drill. But I am looking into building my own CNC router when I get a chance.... I met an electrical engineer that showed me the one he built. It would make my lure building alot more accurate and efficient to say the least. I will say I did use some engineering for my lure turner ... It might be the most unique you have seen on this website. It involves a variable speed drill and neodymium magnets.... (imagination) Also, what I always tell my fiancé... My engineering degree is just my back up plan for my fishing career.

-

EdL, Thank you for the response. I am the same way when building my crankbaits, I build crankbaits because it is fun, it gives me something to do in my down time when im not studying or fishing. In my research study I will most likely be using a 3D printer to make multiple relatively identical baits, size, weight, density. A crankbait's wiggle from my limited knowledge is nothing more than a wavelength, and frequency. If one was so inclined to come up with a mathematical formula in terms of weight, size, density, bill length, width, etc.... you could in essence design a bait to operate a certain frequency for a certain water temperature. I understand water density changes as well.... but that is something that is not controllable or a "fudge factor" With that type of formula though I think it would be very interesting to do a biological study with relatively identical baits that operate at a different frequency (wiggle rate? ) And study what frequency at a certain water temperature draws more strikes from a bass for instance. I know this will be somewhat random but I bet with enough trials it will have some sort of bell curve shape. In the end you could design a crankbait for water temperature ranges (which I understand is already out there in a round about way). But it was this undergraduate research study, or linear algebra, partial differential equations, or physical math.... what would you pick? lol Sorry for the babbling. Cory

-

Okay... I will start off saying that I am currently a 22 year old mechanical engineering major. (3 semesters left ) I will also say that next semester I have convinced one of my professors to allow me to do an undergraduate research study on.... crank baits (awesome huh?). Initially I thought I would like to use my own crank baits, but that is not really practical. My carving/sanding capabilities would never allow for an accurate test of multiple baits. Not to mention wood is not uniformly dense. I could go on forever about this topic but really I was just curious how many members of this site are engineers? So many of the posts I read are so technical, fluid mechanics/dynamics, aerodynamics, etc... Just for fun, and thanks Cory

-

If you go to hobby lobby (or a similar type store) they have things called eraser stencils. I found one with a good semi-circular opening (among others) it works great for me.

-

-

-

Yeah its on the turner right now. It looks like I used red and gold foil on it with some crawfish lines if that makes sense. I can't tell if I like it or not.

-

Well I did a craw pattern with a chartreuse belly, the belly looks very gold now. Its like I made the pattern a metallic craw.

-

Yeah there is old bomber craw pattern that I don't think im capable of painting, im going to try a photo over foil with it.

-

That is a good looking bait Ben. But I was actually talking about using a photo of a chartreuse black back crankbait or a craw pattern photo and printing it and putting it over foil like you would a photofinished bait. Ever tried that?

-

So im probably gonna try the photo finish on a couple of my baits, and something struck me. Has anyone tried to use just a basic crankbait pattern like chartreuse blackback over foil? If so did it work?

-

-

-

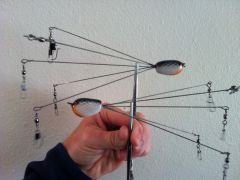

.039" piano wire.... How I made them.... Roughly 3/4" X 1/2" X 1/2" pine block.... (whatever size and wood you want) Drilled a 3/16" hole about 3/8" deep in one side..(will be the back of the head) Drilled a 1/16" hole through the rest of the bait level with the 3/16" hole. Took a short wire and put two 90degree bends in it.... the second bend had to be small enough to fit into the 3/16" hole. Took 5 wires with swivels and put a little hook in them.. (or two long wires bent in half and one more) Hooked them to the short wire and pulled it as far into the bait as possible. I choose to use some galvanized small gauge wire and wrap it around those 5 back wires and push it all the way into the body as well....this takes strain off of the epoxy and wood when you go to bend the wires out. Epoxy everything in then form your hook eye on the front end of the short wire. Seal, Paint, Topcoat.

-

-