aulrich

TU Member-

Posts

535 -

Joined

-

Last visited

-

Days Won

12

Content Type

Profiles

Articles

TU Classifieds

Glossary

Website Links

Forums

Gallery

Store

Everything posted by aulrich

-

My printer is in my basement where the temperature is 18-21c or 64-71 freedom year round. As I understand it the higher end resins like sculpt like it over 30c. do you guys worry about that or do you have your printer in a warmer place than mine. I am just finishing up a heater to go in my printer.

-

I am new to resin printing so this is me guessing, but I had anticipated that flatness was going to be an issue I wonder if you could dose the sculpt resin with some tenacious, maintaining most of the heat resistance and get some flexibility to fix the warping. I don't think pinning the mold to together during the cure would help. One possibility is the speed of the cure it stands to reason that as you blast one side of the mold with UV the cross linking would put an internal stress on the part since it does shrink as it cures. I would not be at all surprised if the curing resin acted like ceramics that have to cool very slowly and evenly after they are fired or they crack. Pull the UV back and rotate the mold like on a lure spinner the slower and more even the cure should help with warping. I had anticipated having to touch the mating surfaces to a glass plate with 800 grit paper to make the surfaces decently flat

-

How durable are the paint jobs on pteg, I thought paint adhesion was one of PTEG's weaknesses? That is one reason I have been using PLA, I had expected to warp some baits but none yet. Some time ago I ran into a YouTube he tested 35% vs 10% with double lines and the 10% double line was as strong and a bit lighter.

-

There was a post from the spring where a guy was casting hard bodies in an FDM mold. I tried it myself but I did not build in enough clearance so it wan just about impossible to get the wire harness and ballast done right. I did have some success printing a mold of a mold the upside is you can adjust the silicon mold easier if you need to expand the pour hole. And rigging the mold for pouring is more forgiving with wire dimensions. One thing I did not do enough of was tuning my printer for dimensional accuracy is did some but the 20mm calibration cubes are not quite enough. errors that don't show up at 20 mm will at 200 mm. Tuning will help with layer lines but the single best mod I did for my printer for layer lines was to make a spool holder that ran on bearings. A coat of CA glue gets all but the worst of the layer lines. From my limited experience with cast bodies I find a printed lure takes less effort. But I will admit that maybe I don't have the practice building harnesses. Up till now my over riding design goal is to end up with a one piece lure blank like it was carved from one piece of wood. I have done screw eyes slotted thru wire and "drilled" through wire. I did a bit of a side by side of cast and printed lures and I actually prefer printed over cast, in the case of that particular body. The printed lure had a slightly better action. This is what I mean by a Mold of a Mold

-

I'll have to get off of my butt and get my stuff up, I just want to make sure they are properly tested. When I tried printed lures the first time they were all duds so it turned me off of the concept for a long time. I got a bit distracted lately Elegoo had a great price on their Saturn 4k so I am in the middle of learning how to work a resin printer that and it's hunting season.

-

Yea I'll have to do some shopping around, this was from a local shop and I don't mind paying a bit of a premium for shopping local but for at least the high end stuff amazon is cheaper. But I do like being able to get some thing in a half hour vs tomorrow so I will still get some stuff local.

-

Yes, just managing costs I did get a bit of sticker shock, for me expensive filament is $40CAD/KG where basic resin is $80 CAD/kg and the high heat or flexible resins increase costs fast.

-

A quick question, I just got myself a resin printer, at least for proto typing can you get away with Standard "abs like" resin then print a "production" mold out of the high heat plastic, when you are sure the body works.

-

You could also give it a quick heat with a hair dryer to give a custom fit. But a flex filament is still the best option. As a side note I am a bit closer on using flexible fillaments

-

I would build my spray booth so that it sucks in all of the over spray and runs the air through something like a furnace filter. if you run any oil paints or organic solvents you would have to run the air through a carbon filter too. A respirator is not a bad idea, but it could give a a false sense of security. Because paint that does not end up on the lure or the back of the spray booth is now dust in you work area. If there is a health threat in acrylic paints it's probably the various salts used for pigments so managing that dust in a small enclosed area is probably the way to go. So add a filtering system to you spray booth area and you should be golden.

-

I think guys have pulled off two plastic pours so clear low with a micro balloon top layer or a two part foaming resin. I have never done that so I can't say. I have seen lure with large hollow inserts but they were soft plastics so not so much for buoyancy but for using less plastic, so maybe a small vial made of a thin walled clear plastic tube.

-

Well now you got me curious. No clear resin in the house but I do have a lipless mold that could work with no micro balloons.

-

A new (to me anyways) tool in the fight with plugging airbrushes

aulrich replied to aulrich's topic in Hard Baits

I could not find any locally and amazon.ca had too long delivery. Since you brought it up I took look at the MSDS and all it says is Ethyl alcohol as far as I understand it the formula given is just anhydrous ethanol so my denatured should have done the same thing Is there is a chemist out there could you validate that? When I was searching around for options (I have DIY reducer so why not restorer) I ran into a airbrushing blog the the person swore by lacquer thinner , and it I knew I could get some locally so I tried it. -

Going on my limited understanding, I don't think you will find a clear resin that will work as you think since resins are are more dense than water. But I think there could be a way around that problem. Roto Molding. You will need a mold without sprue or vents. Fill that mold with enough resin that will give you enough wall thickness for strength but enough air packet for buoyancy. You then pout that mold into a 2 axis spinner that slowly spins the mold on both the x and 4 axis and just like a lure tuner spreads the resin smoothly over the top of a lure the spinner puts an even coat on the inside of the mold. I would think you need a resin with a fairly long pot time Since you will likely need to pour the dose into the mold, degas the resin then mount it in the spinner with enough time to created the even coating. there are probably more issues but IDK. Another option is resin 3d printing lookup gulfstream outdoors on YouTube to see what can be made. it is a whole new can of worms

-

So since I find myself doing a bit more painting than in the last couple of years an old pain had raised it's head the plugging every few minutes pain. At to cut to the chase, lacquer thinner is my airbrush's new best friend. I had soaked my airbrush in denature alcohol and I thought that helped but a quick filling of the bowl and after a minute or two gunk started to come loose. it took about 10 minutes but I don't think the brush was that clean since day 1. I found the idea on an airbrushing blog while trying to find airbrush restorer

-

That does, thanks

-

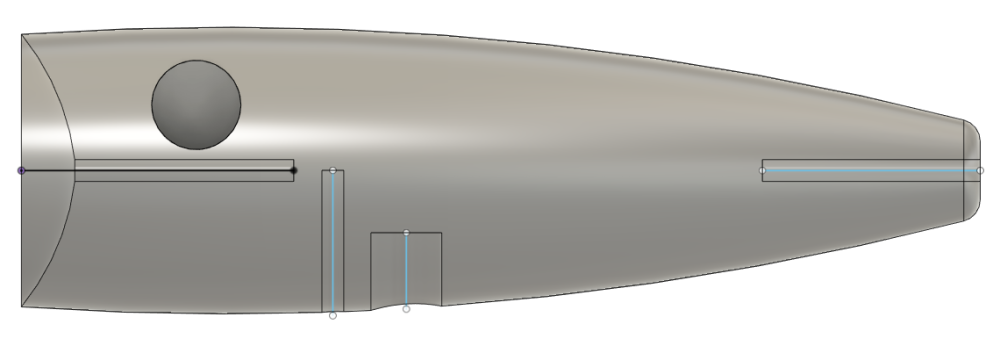

Just dipping my toes into making a freshwater popper the body it 25mm x 88 or 1"x3.5" , as I understand it the ballast should be further back, but just how far. the is is the body in fusion. And since this is a printed lure should I be shooting for a just barely buoyant.

-

So I have been fighting with replicating a lazy Ike type lure, a lot of the issue were related to 3d printing and I did eventually get around them and finally got one to swim but it was barely buoyant, I could have been over hooked #2s on a 88mm (~3.2freedomunits) my hook supply is a bit sparse at the moment :). For some reason I decided to remove the ballast and it still swam. so when you are making a floater diver how to you set you starting ballast weight. Also what would be the signs of instability

-

I have learned a ton from that channel mostly CAD related since I just have an FDM printer at the moment.

-

I have tub tested the printed with foamed PLA and the baits do have a more lively action. I have printed a whole bunch with luck I can field test them sooner than later. My gut tells me they should be fine since the surface finish is sort of rough it bond better to screw eyes and lips. Speaking of lips, I spent the time remodeling the lip since I had a couple of broken lips in the first batch. The lip now look more like a commercial injected molded body. At the body the lip is 2.8-3 mm instead of 2mm. But it tapers to less than 1mm at the leading edge. I also made the lip and corresponding slot "Keyed" so the lip is always centered and straight.

-

Epoxy does need some gap to properly bond. Are you using any release agent on the mold that may not have been cleaned off. A mechanical lock like holes is never a bad idea.

-

Actually vapor smoothing is a common practice at least with some filaments. As an example exposure to acetone fumes will smooth prints from ABS filament. There are smoothing products for prints but simple sanding sealer works even a thin coat of CA glue, CA also is a great sealer and is useful for bonding any layers that did not bond completely, 3d print at least from a FDM printer tend not to be water tight. There is no way to completely avoid sanding. I don't think an FDM printed lure will never win a beauty contest but they do catch fish.

-

Just wanted to report back on the foamed filament, it's very interesting. When I got it I snapped of a chunk and put it in water, and it floated. I did not get the 35% lighter but I did get an average of about 25% so not trivial. I am printing samples of my my bodies to see if there is a noticeable difference. I did find some difference already, it's not quite as stiff as regular PLA, but as long as it is stiff/strong enough I am OK with it. Because it's foam the surface finish is different sort of coarse but that should make it take paint better

-

I have use glow powder in the epoxy top coat with good success.

-

OK this will seem a bit off the wall but, there is a YouTuber called AVE he started this thing called Town Pump CNC. I believe he is open to small custom work. The biggest question is how to get a hold of him maybe the community tab on his channel or his patreon page. He does have a nice 5 axis Haas.