Fishermanbt

TU Member-

Posts

165 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Articles

TU Classifieds

Glossary

Website Links

Forums

Gallery

Store

Everything posted by Fishermanbt

-

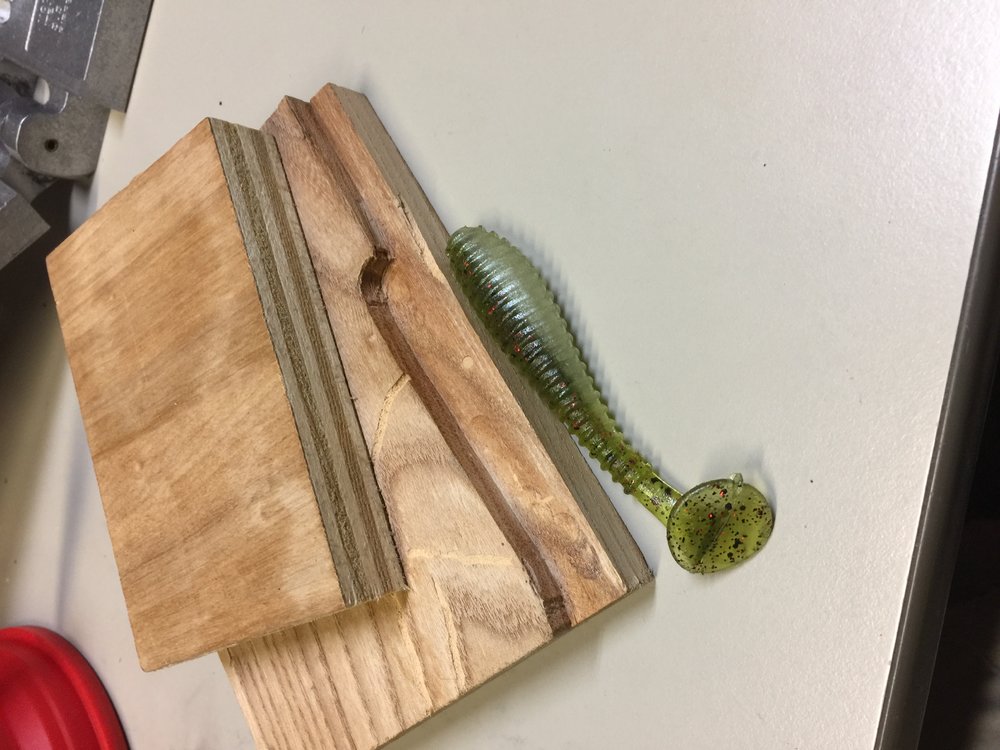

Search title “Aluminum injection mold laminates?”. I posted a picture of how I was able to get laminates by cutting the bait, putting it back in the mold and shooting the next color. Just have to remember to cut the nose at an angle to create a ramp for the next color.

-

I’ve used both epoxy and wood glue with decent results for both. With two part epoxy I thin it down with denatured alcohol and paint it on. Take care not to over fill the bait cavity or you lose details. I put on about 2 or so layerings. The pop will decide when it has enough.

-

Hate to hear you’re having a rough go with the Pyrex. Before I started pouring I had read a few mishaps of this sort and it made me nervous. Don’t know if this will do a thing for me if (when) I have one give up the ghost but here is my valiant attempt at safety. I gather up a few neoprene can cozies each year and slip them over the 1cup I use. Takes a little persuasion but they fit snug. My thought is I’m heating up less mass with a 1 cup, I’m providing a slight amount of insulation for the plastic, I’ve got a buffer between the cup and the counter top, and should it crack or pop most of the shrapnel and hot plastic should stay contained so I can leave dodge. Just my two cents.

-

Another option to consider is using hi temp red gasket rtv. It is not permanent and does well in modded lead head molds. I’m sure it would hold up against hot plastic.

-

When I’m done shooting baits for the year due to fishing and outside work I clean my molds up. I use a scrub brush with soft nylon bristles and an old toothbrush for the cavities with Dawn dish soap. I scrub the entire mold front and back, dry with a towel and then air dry. This winter they will be nice and clean ready to go.

-

Seeking out samples is some great advice either from the mold company directly, or reaching out to members that might have the mold. A few dollars for shipping and a few days will save you money and buyer’s remorse. This way you can see how the bait looks in hand, how the appendages behave, and so forth. You probably won’t get the colors you want but I would at least ask if it were possible to get a mix of light or dark colors. As for your concerns with the sand cast molds, I have a few and they pour just as good as CNC in my opinion. Yes they produce a mat finish on the bait but I don’t see fish being turned off because of it. Easily changed with a can of height temp paint and masking tape

-

I bought a gallon a few weeks back just to try something different from what I had been using. I won’t name the specific brand I was using for the past 2 years but no matter what I did I could not get consistent clear baits or lighter colors without scorching/yellowing. My thoughts thus far a half gallon in is it has its corks but I like it. I have shook the guts out of this stuff with nothing stuck to the bottom. Baits still come out tacky but after say 24 hrs they are pretty much good to go and 48 hrs there is no sticky problem. As stated above by Elf I raised my initial conversion temp to 360-370 and that made an improved difference in curing time. My whites, chartreuse, and clear baits stay true with this plastic no matter how much I reheat. Like people’s choices in beverages, to each his own applies in plastics too.

-

Maybe a cheap manual meat grinder like from harbor freight or eBay?

-

Selling soft baits to friends

Fishermanbt replied to SouthBelleGroveOutdoors's topic in Soft Plastics

As stated above the tax man will come a knocking if you start putting yourself out there on social media. Selling to your buddies I doubt would be that big of an issue though. Two ways to consider the issue as I see it. Tell them to pool their money and you order the materials and make them, or just sell to them for cost of materials. Here’s how I break down my rough cost. Mix and pour one cup of each of your favorite baits. Write down how many baits came from each cup. One gallon of plastic w/ shipping costs say $60. 16 cups in a gallon so $60/16cups= $3.75 per cup. Let’s say you got 24 baits from 1 cup so $3.75/24 baits= .16 cents per bait. Of course you need to factor in cost of power/glitter/colorants/oil and so on. So roughly .20 cents per bait. Same with jigs. 100 hooks=$15; 100 keepers= $10. So divide $15/100= .15 cents each and $10/100= .10 cents each keeper. You have .25 cents in each jig w/o cost of power/powder paint and so on. Hope my math is right and this helps you out. -

Maybe completely not what your interested in but I have a small injector that I use from time to time for this kind of work or other tinkering. I found a metal marinade injector at Lowes in the grill section. Mine came with two long tips. Although not intended for plastic, you can keep it hot on/in a heat source and it’s ready to go when needed. It’s decently accurate but not absolutely the perfect setup.

-

Is bubbling always around where the skirt starts? If you haven’t already done so give the mold a good scrub with Dawn soap and and a brush. Also check to see that the insert is screwed in tight. Looking at your picture it would appear that your getting venting since I can see the little nub on top of the bait.

-

Give air dry clay a try. I’ve done it on a few cnc molds to block off areas. Over fill both areas and clean away excess as needed. Just be sure to give it plenty of time to dry out. Once your done or if you don’t like it scrape the majority off with a plastic knife and scrub with a brush and Dawn soap. Good as new.

-

I made a jig out of wood so I could apply slight pressure on the body while cutting the belly off. Trim the nose at 45 degrees, place both back pieces in mold, and shoot belly color. Crude but effective. Hope this makes sense.

-

Yep, I can see the confusion there now. Well played. Man I’m getting old. Just hope I’m not using the social media version once I get started.

-

Thanks for the info. I also received a follow email from the company that provided me some guidance. I do love me some good customer service.

-

I will be getting a gallon of regular mf plastisol for Christmas. Never used it before so I’m wondering how it will behave with my setup using a microwave. Over the years I’ve used do-it’s plastic with good results. Am I good to go with the age old initial 350 degree mark and 320ish there after, or am I in for some headaches? i contacted mf manufacturing but I suspect that they are busy filling orders right now. Thanks

-

Looking for a do-it mayfly mold. Thanks.

-

Handcarved crawfish crank

Fishermanbt commented on Gastonfishlures's gallery image in Best Homemade Hardbait

-

Well I'll be. There they are. Thanks.

-

Been seeing several musky guys throwing monster tubes. Like 8-12" tubes. Haven't been able to locate the source yet though. "I got them from a friend" is what I keep hearing. Think there's a conspiracy going on. They look great, clean lines, crisp tails, like they came out of an aluminum mold.

-

Yes you did Curt. Keep after it! I appreciate.

-

Clicked the TU logo at top left goes to forum page. Scroll down through list to bait shop. Clicking on the link gets "page does not exist."

-

Doubt you were looking for feed back with this test, but for what it's worth: using my iPhone I got here by selecting upper right corner menu>browse>classifieds>for sale. Tried going through the main page>for sale and get "the page does not exist".

-

Glad to see the site is back up. Thank you for your time and efforts in keeping this wonderful playground open.