-

Posts

688 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Articles

TU Classifieds

Glossary

Website Links

Forums

Gallery

Store

Everything posted by gliders

-

Iphc, dale mentioned createx and wicked, just for clarity Wicked is a createx paint as is auto-air, and what I take it dale means -createx colours. So 3 createx varieties with slightly different properties. Wicked is a safe bet. Hope we're not confusing you!...glider

-

Good stuff dale,crack on........

-

A good history lesson ! And just noticed the title should read-origin of crackle,oops...

-

Thats what I was wondering mark,kind of like a grizzle hackle on some fly patterns. When I say older lures A.Z , i suppose its relative !Woodieb8 I just seen your other post about frog type pattern,thats kinda what I remember, was it just another one day wonder to catch fishermen or did/do they have anything about them in terms of hard results ?

-

So not to sidetrack dales crackle question, I'll ask in separate thread. Why was crackle pattern originally used on lures especially older u.s and canadian lures ? I know the method came from another industry, but why on lures. Was it originally a semi imitative pattern of specific prey like frogs,or was it simply to give a broken up two tone effect ? Thanks...glider

-

I'll ask question about origins in a new topic dale so not sidetracking this.......glider

-

Don't want to sidetrack thread dale or woodie,but always wondered the reason crackle was popular on older American and Canadian lures. Was it originally a suggestion of imitation of a specific prey like frogs or something ? Or was it just to give a broken irregular tone pattern ?. ....glider

-

Have a thin nail embeded in small section of dowell inside pvc pipe section, you can have screw instead ,personaly i prefer a nail, screw can cause damage on way out but more secure.I put a touch super glue on nail for big gliders. When it comes to removal you can either crack the seal with a sharp twist or if you have epoxy build up cut round join with sharp blade first. When you drill hole for nail/screw ,drill shorter hole than length of screw eye. Insert screw eye with enough epoxy to fill hole and wipe excess. Hope this helps.......glider

- 4 replies

-

- musky baits pike baits

- gliders

-

(and 2 more)

Tagged with:

-

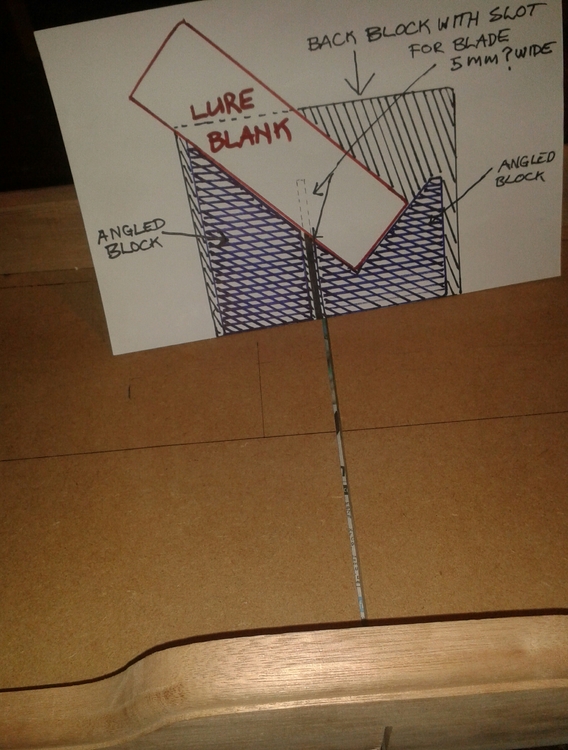

Looks like a good jig dale, final tweak done on mine and am very pleased with results, Does what I was after in terms of adjustment and very quick ,I also made a few more blocks to cover various options,took a bit of time but well worth the effort.Ive not added a clamp but had no issues with blank moving, I might add a quick release type device for safety .Thats not clutter dale,thats neat and organised

-

-

Hi folks,for anyone interested I managed to come up with a sled/jig that gives me adjustment for width,angle and by raising /lowering blade also depth of slot. This gives me the range of angles I need but could be adapted for more. I haven't added anything to clamp the blank down, but down several tests just holding in position and so far so good. Here's some pics and thanks for letting me bounce some ideas about, .....glider

-

Thanks dale,I'm in process of doing something along those lines at the minute . Probably the easiest way of angle adjustment would be pivoting the complete jig ,could then fix angle in various ways. I'm going to put together with bolts so allowing for adaptation if needed. I reckon quick release clamp may be the easiest solution for holding blank if needed ,don't want to lose any more fingers, I'm running out.......glider

-

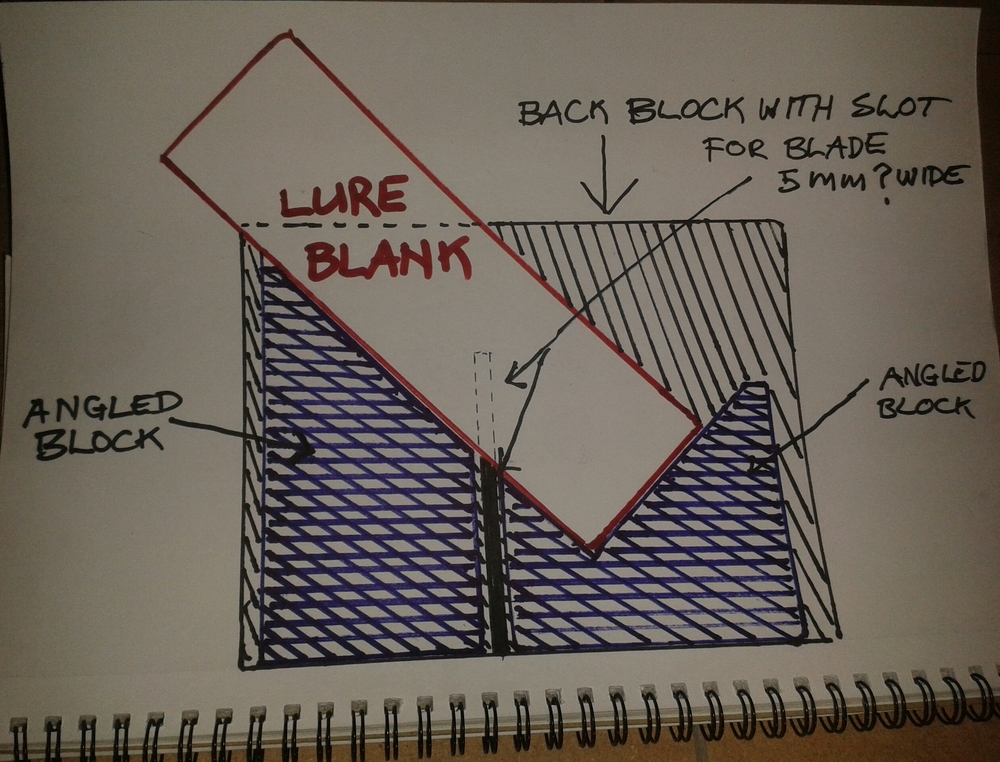

Thanks ben,had learn how to make a sled and ensure it ran true to blade etc. ,took a while but got there ! The reason for 2 blocks was so blade can pass between them. They would be fixed to back block and back block able to slide left and right for varying slot widths using more than 1 pass. Rather than angled blocks flush to sled bed, maybe I could have both on seperate bolts and raised off bottom allowing angle adjustment ? The left block could just be a straight bar and the right block a simple right angle section. Thanks again ben and any other thoughts appreciated. ..........glider

-

This is what I have at the minute guy's , not to scale. The adjustment would be by moving back block with angle blocks attached using bolt and slot possibly, and maybe stops for different width slots. I know the right hand angleblock not strictly necessary but it would give support and ensure repeatability. This is just 1 option I came up with and does not include any means of angle adjustment or fixing to sled ,nor does it include a means of clamping blank to jig yet If necessary. Interested to hear any thoughts ,(was thinking Vman might have an opinion but he seems to have went soft !)

-

Been using bandsaw for some time dale,great for small to medium cranks ,not so much for 3-6mm lexan bills. It works o.k ,I have no problem with misaligned slots at all. However with a well designed jig setup and table saw, a perfect slot should be guaranteed every time, Any size,width or depth. I'm convinced that done properly it will be a superior method. (Plus I've just bought a bigger table saw and built a sled for this!) Also it might be possible to do 2 or 3 at a time......step up mcgiver. .....glder

-

Hard to tell from pic ,should add , I based mix on transparents over white.

-

Anytime now the designs will be pouring fourth......

-

Think a lot depends on paint used,if I was mixing that I would start with say 6 parts yellow,1 part red and 1 part blue,this will give a redish olive which is what I see in picture, If its erring toward being too redish an olive then add 1 more part blue. Don't know if that's any help, or you're looking for a ready mixed colour.......glider

-

O.k guy's, I've built sled for table saw, let the avalanche of wondrously designed lure blank jig contraptions begin !

-

Hey dauds,thats what this jig is for,will be along similar lines probably. This is specifically for big lures with 3mm + lexan . The majority on T.A make mostly bass size lures I suppose, others make everything so different requirements. Again, thanks all for input. Will check in tomorrow and see if anyone got anything else,cheers.........glider

-

Thanks ben,thats pretty much what I'm thinking, if i have blank on jig, then move/adjust jig ,forward or back to allow for various slot width using 1,2 or 3 passes, I'm thinking If i get design right then I would still have shim/ stop option. My reason for vertical blade/ angled lure blank versus angled blade/ flat lure blank is the former only needs 1 adjustment ,forward or back as opposed to angled blade which would need forward or back and up or down be it the blank or blade or jig to achieve same goal. Its surprised me that there's actually not more table saw setups out there. I've toyed with idea of moving from bandsaw to table saw for maybe 2 years and think I've seen 3 or 4 setups. .........glider

-

That is a good idea.

-

Duad,I think most cut while blank flat sided so as to achieve straight across cut ,certainly it's what I do. On the bandsaw I find it makes no difference if rectangular or outline shape as long as it's flat.

-

Thanks dale,the easiest thing would have been sticking with bandsaw ! But I've always fancied for the bigger cranks I make that a decent tablesaw jig/sled would be superior. Going down the route of vertical blade and therefore angled blank to achieve slot width adjustability meant I needed a bigger table saw ,blades,jigs,sleds etc!. I'm still undecided about design of the actual jig/contraption /method. The sled is almost done so I'm looking to crack on. On a different note-muskie glen,do you mean you're using mitre fence instead of sled ?..........glider

-

Skeetermanind, your best bet is to use the search for each question you have,i.e best airbrush ,lure bodies etc. Loads of good stuff in there. Worth Spending a fair bit of time doing research before deciding way ahead,good luck.....glider