Hillbilly voodoo

TU Member-

Posts

1,138 -

Joined

-

Last visited

-

Days Won

90

Content Type

Profiles

Articles

TU Classifieds

Glossary

Website Links

Forums

Gallery

Store

Everything posted by Hillbilly voodoo

-

0CD5349C-242B-4613-8F67-81265C2164BA

Hillbilly voodoo posted a gallery image in Best Homemade Hardbait

-

So after all they messing around with different ideas I have settled on this design. This is my first fully finished surface paddler.

-

Tricks for painting small spots (trout pattern)

Hillbilly voodoo replied to Hillbilly voodoo's topic in Hard Baits

I gave the sharpie a try a few days ago and it works well I have actually found all the advice in this thread beneficial and adapted to different patterns. -

To keep it cost effective and time efficient you don’t have many options beyond bags, blisters, or tubes you mentioned. The only other option I can think of is a cardboard box with a clear plastic side I would be interested in what you finally go with because I may be facing this issue in the future

-

Good catch I completely missed those beads have a flat top and bottom

-

7AEADF54-9284-45F6-8739-0C53615BBD29

Hillbilly voodoo commented on Hillbilly voodoo's gallery image in Best Fly

-

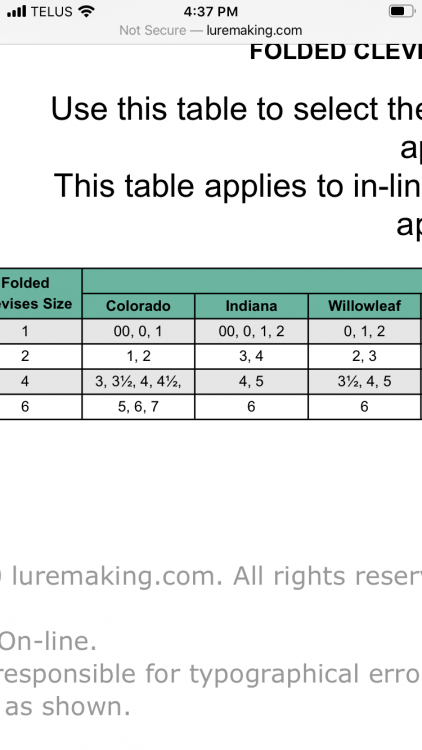

The chart is from the website of one of the lure part suppliers I use here in Canada. Names in the screen shot. You will find the chart in the clevis section

-

Been a long time since I have made in lines that small but if I remember correctly if your clevis is too large you are going to have issues. Here is a screenshot of a chart to match sizes at this moment the clevis is the last issue I can think of

-

So even reeling at high speed no spin? are they riding on a steep angle hook down? willow leaf in lines can be picky unless they are a wide version

-

-

What Mark said you need a clevis with those blades. You need smaller beads to space the blade away from the larger bead. The large bead is robbing the spin the spinner in the top pic toadfrog posted gives and example on what you need to do. He used the smaller beads to space the blade away from the bell body

-

@Vodkaman do to your location I could see this issue being whole different ball game Make sure you take time to enjoy some of that vodka and stay safe Dave @ravenlures Sounds like your on the same path as I am got nothing better to do then build. No lock down here yet but probably on its way. Laid off, stuck home schooling kids, and not much do either way stay healthy and hopefully you enter one of your projects in the contest so we can see what you come up with

-

The one thing with this mess I actually have the two new designs I wanted done for this season complete and getting molded this week I might have to revisit my paddle tail hard bait or maybe another top water or glide/jerk bait At least this hobby can help pass the time

-

Will do Comes in handy having a wife and other family that work in health care sometimes. With all the miss information and fear mongering it’s nice to get opinions from people who are actually dealing with this in the healthcare sector now go build something interesting for the lure contest

-

Rag works too personally In models where I glue in the lip rather then have it molded into the body I install the lip after I am finished with my acetone cleaning. It just takes away the risk and allows me to be fast and sloppy without worry of wrecking the lip

-

I learned the hard way acetone also weakens lexan. Tried to clean epoxy off of a lip on personal bait with acetone in the past. Dropped the bait off the table an that was enough to break the 1/8 lexan lip Also the wife bought me some disposable cups that ended up being made of some corn syrup base or something along those lines. Don’t put acetone in these it eats through them in seconds. acetone is handy but can screw things up to

-

Mark just bugged the wife for you My wife works in the hospital and knows all the medical cleaning precautions. She says warm water and light soap for fruit and veg if you’re not cooking it just rinse throughly so you don’t blow bubbles well eating it lol

-

It’s sure been quiet hope all are doing well No Covid19 in my town but lay offs are more common then TP with all the cuts to non mandatory services do to the virus and oil prices Laid off and home schooling kids do to school closures makes a guy miss work lol

-

I have never dipped a hard bait in plastisol but I bet it would look like a bad sunburn peeling after one musky or pike it would probably look cool till it got bit

-

The method I had planned for a similar 9” bait was as followed 1)take a 1/2 spade bit and drill a 3/4 inch hole in the front section hard section 2)glue a half in by 3/4 piece of dowling on the master for your rubber tail. of course be sure it will line up the joint evenly front and back this way you will have a rubber peg coming off of your tail that fits into the hard front section. This will give you a pressure fit and larger glueing surface. It will also line up your two halves nicely I have seen variations of this along with dove tail and slot/rail style joints used on hybrid baits The rapalas hybrid joint I think is more about giving a solid anchor point for the hook instead of running a wire leader from the front and sinking the hook into the rubber or a corkscrew/spur peg

-

Got my micro balloons sorted but will check out industrial paint and plastics to see if it’s more cost effective Let me know how the laser cutter works out. I went with the 3D printed templates and trimmer method I mentioned before. It works well but I am always looking for better options Now if only everything would hurry up and thaw out so I can go fishing/test some new lures

-

Like Travis said dip away I wipe my resin baits to clean oils and dust off before painting

-

Sounds like your just as bad as me screw it just build with what you have on hand have you considered building a keyed joint and just glue it for your joint? That was my plan for the hybrid project I have temporarily shelved

-

I have used just sanded cedar no issues. With my hard bait molds I do find is your master has been clear coated with epoxy you get a really nice smooth mold

-

I make molds with smooth on mold max with wood masters no real issue sticking to wood. I do spray with mold release but that is because I make two piece molds