Search the Community

Showing results for 'dents'.

-

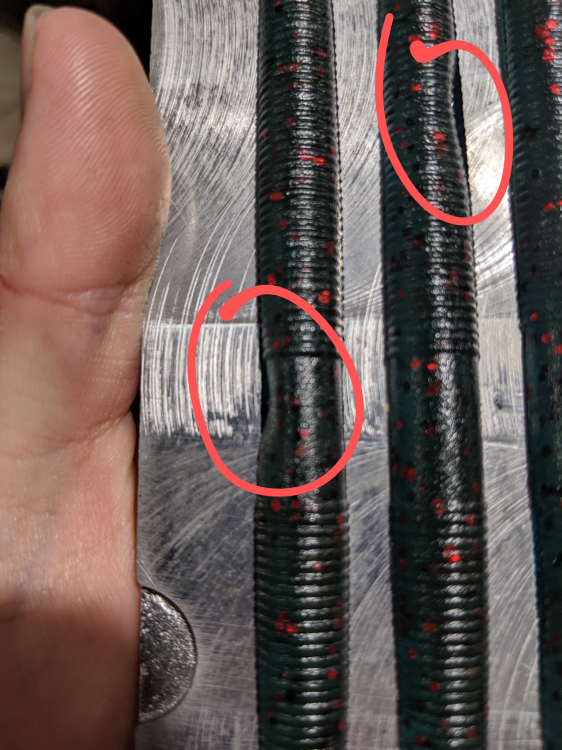

I'm shooting a couple of ribbed grub molds, 5'' and 7''. Everything is fine except there are these weird little indents, only on the top side, on each rib. I'm not new to shooting molds at all and I've tried everything. Could this be a venting issue or is it something else. Any help would be great.

-

Hey guys. I’ve read about 25 threads on dents and almost all of them have to do with the stick bait “thumb” dent. I’m looking for advice on eliminating these dents on my curly tail lurecraft mold. I’ve shot between 320 and 350 fast and slow. Just can’t get rid of them. Using Bait plastic 262 blend. ***EDIT: I also hold pressure 10-15 seconds each time

-

New here great forum can't wait to learn a bunch of stuff from everybody, I do have a quick question I just got my first mold (5" senkos do-it essential) I have made about 10 sets now and every so often some of the worms have dents in them. I have read this could be due to injecting to hot/fast or clamps in certain spots, it typically happens towards the back end of the worm..any help with be appreciated. Injecting these in the pictures at 330, but I have injected at 345-350 and ended up with dents as well...also I am topping off at the end. Using the soft plastic(152) from baitplastic.com if that helps

-

Hey guys check out the link below.. if someone can make it show up without having to click the link that'd be awesome. i keep getting these inconsistent dents.. I've tried slower speed injecting, faster, more pressure after mold is full. Using ES beaver bug mold. Thanks for any help. Plastics around 345-355. http://tinypic.com/r/20utw7a/9

-

Hi guys so im having a problem shooting some worms to be exact round finess worm and a strech 40 type lure. Both molds are hand pour molds but i use my injector on them. Everytime i shoot them only one of four lures come out right the rest have dents in them where the plastisol doesnt take on the molds shape. So question is what can i do to eliminate this problem or what am i doing wrong?

-

I'm getting alot of air pockets (mostly in the tail section) and random dents in my injection senko style baits. I've tried holding pressure up to 10 seconds which has helped some but not totally . Actually having this problem with most of my molds . Is this a temperature issue or something else ? Thanks , Brad

-

Here is something I can't figure out and need help. This could be very simple I hope. Sometimes when I inject a mold I get what I would describe as a thumb print on the sides of some worms. It's a indention like you would press your thumb on the side of a too worm worm. It can be only on one or maybe two or none at all in the pour. They are there when I first open the mold up. Is it a heat problem? or what. Any Ideas. Thanks.

-

I think it's from the plastic/mold getting to hot. So if I'm right does anybody have a suggestion on how to keep the molds cool? I'm guessing buy more molds?

-

Hi, I made an RTV mold from clay master. The mold has a smooth inside. But when I looked at the poured bait it has some small dents in the surface. I tried to use clear plastic at 350 F with no bubbles but still the same result. I also received a bait sample from Lurecraft and that bait has similar dents in the surface? Any suggestions to avoid dents. I also sprayed the mold with worm oil but still the same result. I´ve made some POP molds and the baits has no dents. I attach a picture from Lurecraft website to show the dents in the bait. Crappy picture but it shows the dents. /Joakim

-

Hey guys.. I know there are some guys out there who struggle with 'dents' when hand pouring stick baits in a two-peice mold. I wanted to introduce a stick bait to my product line, so a few weeks ago I bought my first stick bait mold. I had never had 'dent' problems prior to this, and my first 200-300 sticks were flawless. After these, however, I started noticing dents. Then they got worse and worse. I didn't change my pouring technique, recipe, anything. They just randomly started getting worse. Even when my mold was cold. I struggled to find a solution to the problem and tried everything. After reading the 'dent' post on here, I read an idea about pouring the worm half and half. I tried that and it worked on my first pour, however after that, the dents just moved up. Previously, all the dents were on the same side in the same place on ALL the worms... right in the middle of the 'ring' on the worm, where the hook goes. And I finally found the solution.. it takes more time, but it worked for me 100% of the time.. I pour half the worm in each cavity.. then by the time I'm done pouring all the cavities, I start back at the first one and pour 25% of the worm on each cavity, then pour the last 25% of the worm. I know it sacrifices time, but with the amount of sticks I had with 'dents' in 'em, I had to do something. So for the few out there that really struggle with dents, this worked for me. My sticks are now perfect. Hoped this helped somebody.

-

I have been ordering blank K.O.s to practice my painting skills, was hoping to get some advice on dents and tool marks. Tried doing a thin coat of etex and throw it on the turner, took the dents out and gave it a very nice and smooth finish, and then I realized the eye sockets had leveled out as well :*( Thought about it and I can't really put the eyes in and then the etex, it would be a PITA to mask the eyes off while under epoxy. And I'm worried if I paint it first then the dents will show through the paint even after the topcoat, slap me with some words of wisdom TU!

-

I have (3) four cavity 702 Craw molds from BT... I am consistently getting unconsistent bait results from these molds... Right where the thickest part of the claw is, I am getting what looks like "suckback" air dents... It is not consistent from mold to mold or injection to injection... They do not look like air bubbles that have burst, but they look like the type of dents that you would normally get from not topping off your sprue or holding pressure... I am confused because I tend to do both of those things, normally I hold pressure and top of my sprues... I love the baits the molds produce, but it really sucks when you cannot get consistent looking baits from mold to mold or injection to injection... Any help is greatly appreciated... Thanks!!!

-

Alright, I have done my research and have not found the solution yet. I am getting dents every time I inject my stick mold. It is a 5 cavity 5.25" mold. It is not from demolding to soon as I have waited up to 10 mins to demold still have dents. I have varied my injection speed from fast to so slow the injector clogged. How long should the injection process take? (from the time the injector is place in the mold, til the mold is full). I am using a 1/3 cup of salt for 1 cup of plastic. Any help would be greatly appreciated. It is a side port injection. Also the dents are usually close to the middle of the baits.

-

I am having some problems with dents in the nose of my injection flukes. The mold is del's 5 inch injection fluke mold. When I first start they will be good then after about 3 or 4 shoots then they start denting in the nose. I have varied the temp from 350 down to 310 and it still does it. I have also varied the about of salt, 2 tbps per cup of plastic for mf medium plastic and 1 tbps per cup of plastic for mf soft sinking plastic. I'm not sure whats going on. I have a 4.2 BT Bomb and double the salt mixtures and I have never had one dent. Don't know exactly whats going on. Any help would be great.

-

i have bears 4 inch stick worm 5 cavity injected and most of my worms are coming out with dents in the bait. any tips?

-

Hi I am new at this. I have netcrafts plastic stik molds and injector and when i fill them to the top and let cool then take them out of the mold there are dents in the worms. What do i do to fix the problem? All info is appreciated. Thanks

-

Forgive me if this is common knowledge around here. I just discovered this and had to share! This has been plaguing me on certain leadheads from the beginning of this pouring addiction. On some of my pours, I would get a dent or crater on the flat side of the Style "9" Shad Head out of a Do-it mold. Also in the bottom of the eye sockets of some molds. Never could figure out why. Assumed that it was a lead temperature issue because I was using a small "Hot Pot" melter to heat and pour my heads(lead not getting hot enough) Example of a typical dent Recently got a thermostatically controlled Lee Magnum Melter so the lead should get plenty hot now Did some "warm up" pours in my mold and got this result. Did several more "practice" pours and kept getting the same results even after the mold was good and hot I always coat my molds with candle soot. Many times by reapplying more soot, it will cure pouring issues. Heavily coated cavity I figure the more the better, right? Not so! Just as an experiment, I decided to wipe the soot from the cavity ...And on the next pour, got this If you will notice, the lead surface is not real smooth. In fact you can clearly see the layers as the lead was poured in, but the crater was gone! There's probably a compromise between "just enough soot" and "too much soot" If you ever have this issue while pouring, try a little wiping of the cavity. Scott

-

Made some twopiece molds for myself out of pop. they turned out nice except that most of the baits come out with a dent in them. i am giving them plenty of cooling time so i don't think early demolding is the problem. Any ideas. The mold is a 5'' fat senko style bait.

-

I am pouring the 6 inch Dels T Stick. I am getting dents in at least 2 out of 4 baits each time I pour. I have tried slowing down, thinner stream, etc.. I have read other suggestions on the forum, but cannot prevent them. I assume it is because it is such a bigger bait and more plastic involved. Any other remedies? Thanks