Search the Community

Showing results for tags 'epoxy coating'.

-

Dear lure maker community, I have a couple of old lures which I don't use since I don't like the color much. After watching lure foiling videos on youtube I thought I give it a try and upgrade those lures with a little bit of flash. After some trial an error, I am happy with the foiling result. I used Tesa Aluminum Tape from a local hardware store (https://www.tesa.com/en/consumer/tesa-aluminium-tape.html). I also polished some of the lures to achieve an almost mirror like finish and I believe it looks great. Now I wanted to seal the foil to preserve the sheen and then start with (spray can) painting. I am using a UV cure Epoxy from a local craft shop. I have used this to seal some beaten up lures without foil and it has been working fine. I cleaned the lures thoroughly with Isopropanol and afterwards only touched it with gloves but much to my surprise the paining fails instantly. The Epoxy pulls together in blobs rather than forming a surface. I had to clean the lure again since the result cannot be worked with. Later test also revealed that the Epoxy does not stick to the surface. Then I tested household Aluminum foil - works like a charm without any issue. Not only does the Epoxy cover the foil evenly, it also sticks extremely well. I tried cleaning the tape with different solvents (see picture) but also mere soap, or Acetone, Phosphoric- and Citric-acid.. Nothing works. Sanding had some effect but also completely destroyed the luster of the foil. Tesa has no indication about any surface treatment of the foil. It only states "Adhesive on Aluminum Carrier foil" on their MSDS. I noticed that the foil is super water repellent: When I put it in a container to do some testing, water would build around the foil covering the whole bottom before finally touching the foil so seemingly the surface is extremely water repellent. What am I doing wrong? Whatever TESA has covered the foil with, how do I get it off? If I need to go through the foiling again with a different tape - how do I make sure I am not getting a product with the same issue? Any advice greatly appreciated. Best regards Lukas

- 9 replies

-

- epoxy coating

- foil lure

-

(and 1 more)

Tagged with:

-

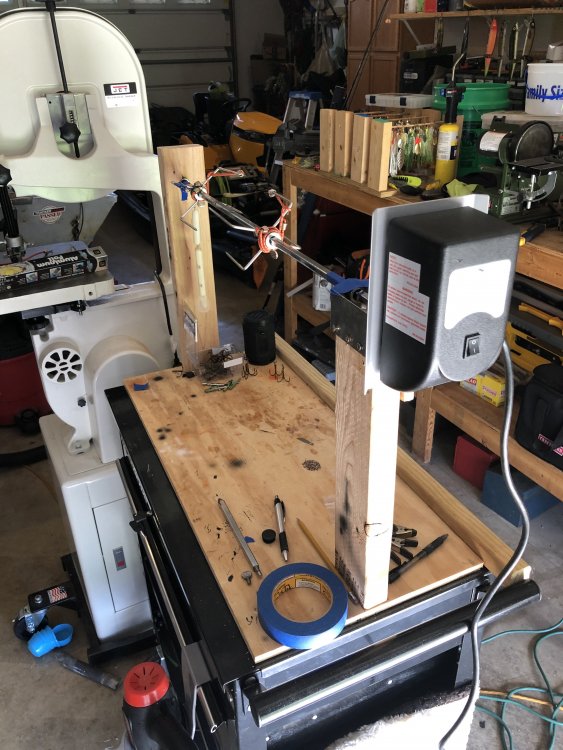

I have been painting/making my own spinnerbaits and plastic/wooden baits for the last few years with airbrush and createx paints. I haven’t had many issues at all with epoxies until now. I made a cheap fast lure turner with a grill rotisserie set up, and I turn lures to dry overnight in my heated garage. I live in the northwest, and the current temps out are 55-60 degrees with around 50% humidity. I keep the garage heated between 65-70 any time I am painting or clear coating my lures. I purchased extra large jointed musky crankbaits from barlows tackle. Every single one of these baits have had epoxy issues on the turner. I have used devcon2ton 30 minute, flex coat gel, East coast resin, and true coat to coat my lures. I had success with d2ton on smaller lures not on a turner. I also had success with east coast resin on a musky bait in a turner, but it took 3 or 4 coats to even out. Most large baits I make are taking multiple coats to get looking nice on the turner, when I had very little issues without a turner and devcon2ton on small baits. I am going to try some smaller baits again to see if I have the same success as before. All of my bigger baits seem to have some minor issues with waves or pitting, and it is getting discouraging. I also wipe down my plastic baits with alcohol before painting them and do not touch any part of the baits before epoxy. I am hoping to get more experienced help on this topic. Here are my questions: 1. These jointed musky baits are made of a different plastic than the others. Could this be the reason I am having all these sudden issues? I have heard of spraying createx clear coat Over the paint before epoxy, and this is supposed to help trap impurities that affect the epoxy?? I ordered some of this and will try, but I am also worried about spraying this clear coat through my nice air brushes and having cleaning/clogging issues. Any advice on this? These Musky baits have been the primary issue, but I had some issues on a large wooden jerk bait also recently that took numerous coats to fix 2. I was worried that vibrations from my rotisserie motor traveling down the turning rod may be causing the waves in the final cure. I have installed rubber grommets on all the fastening screws for the motor to help this morning. I still feel light vibration when I touch the turning rod. Could this cause issues? Advice? I posted a few pics of set up/ baits with waves on finish. This site has been a great help in starting out, and this is my first actual post.

-

I've got a bunch of lures turning right now, and I can see fish eyes developing. Just wanted to check whether my fixing idea is good enough. Just to give some background, I've got an assortment of crankbaits and poppers on the rack, hand painted (don't have an airbrush) with acrylic paints. This first clear coat is with 24 hour epoxy, and I honestly didn't know that contaminants from my hands could cause divots to form in the epoxy. Live and learn, I guess. What I'm thinking of doing tomorrow, once this lot's hardened, is sand them down a little, then give the lures a quick rub down with a bit of soapy water on some tissue paper (I'll be wearing gloves this time) to get rid of any contaminants. Then I'm going to wipe them down with a damp bit of tissue, then dry them off. Once all this is done, the second coat goes on. Do you think this will work?

-

Hi guys, Pretty new in this forum but been painting for a couple of years now. I have always been using Devcon 2-ton epoxy for my lures and no complains to the finish and durable results. But now I am looking at painting matte finished lures. Any advise on what epoxy or coating I can use to produce the matte finish that is equally as durable as devcon? Thanks in advance!